High-strength steel (HSS) repairs require certified welding techniques for structural integrity and aesthetic outcomes. Laser, TIG, and MIG welding cater to various needs, with precision and minimal heat for delicate repairs or versatility for structural reinforcement. Skilled welders use specialized knowledge and precise control to ensure bonds stronger than the original material in auto body repairs, tire services, and paintless dent repair.

High-strength steel structures demand precise repairs to maintain their integrity. This article delves into the art of utilizing certified welding techniques for effective high-strength steel repairs. We explore the unique properties and common damage modes of these materials, guiding you through the selection of appropriate welding methods. By mastering specific procedures, professionals can achieve superior repair outcomes, ensuring structural strength and reliability. Discover best practices to navigate this intricate process efficiently.

- Understanding High-Strength Steel Properties and Damage

- Selecting Appropriate Certified Welding Techniques

- Mastering Welding Procedures for Optimal Repairs

Understanding High-Strength Steel Properties and Damage

High-strength steel (HSS) is a versatile material renowned for its exceptional strength and durability. When it comes to repairs, understanding HSS properties is paramount. This advanced alloy is commonly used in demanding applications like automotive components, industrial machinery, and infrastructure due to its superior tensile strength and resistance to corrosion. However, over time, HSS structures can sustain various forms of damage, including fatigue cracks, corrosion, and impact-induced deformations.

Identifying these issues accurately is crucial for successful repairs. Certified welding techniques play a pivotal role in ensuring structural integrity. Skilled welders employ specialized knowledge to assess and address inherent material properties during the repair process, be it through precision cutting, tailored welding procedures, or incorporating advanced alloys. This meticulous approach guarantees that auto body repairs, tire services, or even paintless dent repair techniques complement the unique characteristics of HSS, leading to robust and long-lasting solutions.

Selecting Appropriate Certified Welding Techniques

When it comes to high-strength steel repairs, selecting the right certified welding techniques is paramount. The choice of technique depends on various factors, including the type and extent of damage, structural integrity requirements, and desired aesthetic outcomes. For instance, while car damage repair often involves precise, localized welding to strengthen specific components without compromising overall structure, frame straightening may necessitate more robust techniques to realign and reinforce major structural elements.

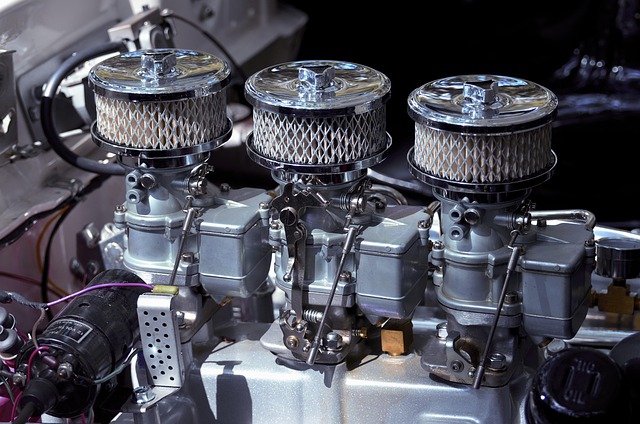

Understanding these nuances is crucial for effective tire services and overall vehicle performance. Certified professionals employ different welding processes such as laser welding, TIG (Tungsten Inert Gas) welding, or MIG (Metal Inert Gas) welding, each with its own advantages. Laser welding, for example, offers exceptional precision and minimal heat input, ideal for delicate repairs. Conversely, TIG and MIG welding are versatile, suitable for both structural reinforcement and cosmetic touches, making them valuable tools in the car damage repair and frame straightening arsenal.

Mastering Welding Procedures for Optimal Repairs

Mastering Welding Procedures for Optimal Repairs is paramount when undertaking High-Strength Steel repairs, particularly in domains such as vehicle restoration and fleet repair services. Certified welding techniques play a pivotal role in ensuring structural integrity and longevity of the repairs. Skilled welders employ specific methods tailored to the unique properties of high-strength steel, factoring in factors like composition, temperature, and joint design to achieve robust fusion.

These specialized procedures encompass precise heat input control, appropriate shielding gas selection, and meticulous manipulation of welding equipment. The goal is not just to join metals but to forge a bond that surpasses the strength of the original material, preventing weaknesses or stress points that could compromise the vehicle repair or fleet maintenance efforts.

Certified welding techniques are essential for achieving high-quality repairs in high-strength steel. By understanding the unique properties and potential damage of this material, along with selecting the right welding methods, professionals can master optimal repair processes. This ensures structural integrity, longevity, and safety in various industries that rely on these strong and durable materials. Implementing certified welding practices is a game-changer for maintaining the reliability of high-strength steel components.